Bringing new competitiveness to Japan’s automobile industry with rare earth-free high-performance motors

Masatsugu Takemoto, Doctor of Engineering,

Associate Professor of the Graduate School of Information Science and Technology, Hokkaido University,

Division of Systems Science and Informatics, Research Group of System Synthesis, Electric Energy Conversion Laboratory

Profile:

Completed master’s degree in electrical engineering from the Graduate School of Engineering, Tokyo University of Science, in 1999, and PhD in electrical engineering from the Graduate School of Engineering, Tokyo Institute of Technology, in 2005. After stints as assistant and lecturer at the Tokyo Institute of Technology and Musashi Institute of Technology (renamed Tokyo City University in 2009), he assumed his current position in 2008. To this day, he has been engaged in the research of power electronics. He is especially focused on the development of electromagnetic devices such as bearingless motors and high-output/highly-efficient permanent magnet synchronous motors for hybrid electric vehicles. Member of the Institute of Electrical Engineers of Japan (IEEJ), Japan Society of Applied Electromagnetics and Mechanics (JSAEM), and the Institute of Electrical and Electronics Engineers (IEEE).

Contributing to the automobile industry with development of motor technologies

Associate Professor Takemoto, you have been researching motors for many years. What is your primary focus?

Takemoto: Electrical energy in society today is like air and water. We can’t live with it. What’s more, motors consume about 55 percent of the total electrical energy in Japan. Improving the performance of motors has therefore become one of the most important research themes for effectively utilizing electrical energy. Researchers have been studying various types of motors for a while now. I am especially engaged in the research of motors used to drive hybrid electric vehicles (HEVs).

Current motors for HEVs use neodymium magnets (Explanation 1), which are made of rare earth elements. But in recent years, countries have become dependent on China for more than 90 percent of the world’s rare earth production. This has led to issues like skyrocketing prices and export restrictions. It is important to develop rare earth-free motors, which are less expensive and in more stable supply, in order to spread hybrid cars and electric cars rapidly. So in 2008 I joined the “High-Performance Battery System for Next-generation Vehicles” project, established by New Energy and Industrial Technology Development Organization (NEDO), and tackled the development of ferrite magnet motors for HEVs (Explanation 2).

New motor concept borne from rare earth substitute materials

How do ferrite magnet motors for HEVs work?

Takemoto: At first, we thought that we could obtain sufficient output with ferrite magnets simply by extending conventional neodymium magnet motors. But after carrying out analysis, we understood that the properties of neodymium magnets and ferrite magnets differ significantly. We couldn’t just replace neodymium magnets with ferrite magnets. We had to rethink the design of the motor itself.

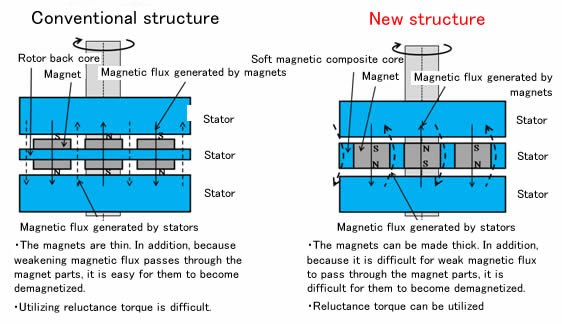

We were able to develop the concept of a motor design specialized for ferrite magnets (Explanation 3/Figure 1) relatively quickly. But what was really difficult was finalizing the design. Because automobile motors require a high level of performance, all components must fit together meticulously, down to the smallest parts. And, in addition to performance, we had to optimize detailed parts so we could arrive at a design that withstands production and industrial productization requirements, all the while conducting repeated simulations and analysis.

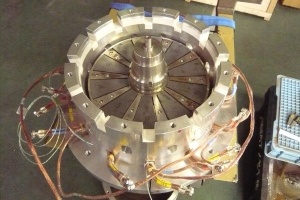

Our efforts culminated in the development of a “newly-structured 50 kW ferrite magnet motor for hybrid electric vehicles,” which was jointly announced with NEDO in September 2010. We developed a motor that could generate 50 kW of power, rivaling rare earth-using neodymium magnet motors for HEVs. This achievement has great promise for strengthening Japan’s competitiveness in the development of next-generation automobiles, which has intensified in recent years.

What kind of changes will the commercialization of ferrite magnet motors bring?

Takemoto: I think a major achievement is the ability to use ferrite magnets in devices that are easy to industrialize. But in actuality, we will still need to use rare earth elements in the future. Rare earth neodymium magnet motors are extremely high-performance, and their designs and production techniques are advanced. Because of this, there are also students in our lab who are researching ways improve the design and performance of neodymium magnet motors. What we are aiming for is not a simple “let’s rid ourselves of rare earth,” but developing alternative methods so we can continue to use rare earth materials effectively from here on. I think it is important to broaden the range of choices. For example, we can use rare earth for high-performance luxury cars, while using alternative materials for inexpensive compact cars.

Amassing experience to create engineering beneficial to society

What do you want students to learn through research activities?

Takemoto: What I keep in mind in my research activities every day is “it doesn’t end with just simulations.” We must also be sure to carry out productions and trials.

Even if something perfect could be created in a computer, unless it is actually produced in real life, it can’t benefit society. I want students to not simply pursue analysis or simulation data, but to also experience the importance of making prototypes with their own hands.

We engineers are called upon to constantly create new things. But new ideas don’t just appear out of the blue. You draw out new concepts by making new discoveries from the experiences and knowledge you have gained, combining them, and looking at them from a new angle. I want to nurture engineers who are intimately familiar with this art of production.

Explanation

Explanation 1: Neodymium magnets

Neodymium magnets are permanent magnets made from alloys of rare earth elements such as neodymium. They have extremely strong magnetic force. Besides motors for HEVs, they are also used in many home electronic products, such as hard disk drives, mobile phones, and personal computers.

Explanation 2:Ferrite magnets

Ferrite magnets are commonly available magnets such as bar magnets and magnet products used in small motors, homes, and offices. Their prices are 1/10th of the prices of neodymium magnets. They hold promise as an alternative for rare earth magnets.

Explanation 3/Figure 1:Rare earth-free newly-structured 50 kW ferrite magnet motor for hybrid electric vehicles

By using a segment structure in the motor whereby ferrite magnets and soft magnetic composite cores are alternated, the motor is rotated by two types of torques – magnetic torque (force produced by the magnets’ attraction and repulsion of each other) and reluctance torque (force due to the magnets’ attraction to iron). This produces output that rivals conventional rare earth magnet motors for HEVs.